Cast steel shot S280

Product Description

Specifications of Cast Steel Shot

| Mesh | mm | SS~2.5 | SS~2.0 | SS~1.7 | SS~1.4 | SS~1.2 | SS~1.0 | SS~0.8 | SS~0.6 | SS~0.5 | SS~0.3 | SS~0.2 |

| 7 | 2.80 | all pass | ||||||||||

| 8 | 2.36 | all pass | ||||||||||

| 10 | 2.00 | 85%min | all pass | all pass | ||||||||

| 12 | 1.70 | 97%min | 85%min | all pass | ||||||||

| 14 | 1.40 | 97%min | 85%min | 5%max | all pass | |||||||

| 16 | 1.18 | 97%min | 85%min | all pass | ||||||||

| 18 | 1.00 | 96%min | 85%min | all pass | ||||||||

| 20 | 0.850 | 96%min | 85%min | all pass | ||||||||

| 25 | 0.710 | 96%min | 85%min | |||||||||

| 30 | 0.600 | 96%min | 85%min | all pass | ||||||||

| 35 | 0.500 | 97%min | 85%min | 10%max | ||||||||

| 40 | 0.425 | 97%min | all pass | |||||||||

| 45 | 0.355 | 80%min | 10%max | |||||||||

| 50 | 0.300 | 90%min | ||||||||||

| 80 | 0.018 | 80%min | ||||||||||

| 120 | 0.125 | 90%min | ||||||||||

| 200 | 0.075 | |||||||||||

| 325 | 0.045 | |||||||||||

| SAE | S~780 | S~660 | S~550 | S~460 | S~390 | S~330 | S~280 | S~230 | S~170 | S~110 | S~70 | |

Technique Index

| Item | Cast steel shot | |

| Chemical Compostion | C% | 0.80~1.20 |

| Si% | 0.40~1.20 | |

| Mn% | 0.35~1.20 | |

| S% | ≤0.05 | |

| P℅ | ≤0.05 | |

| Hardness (HV under 500g load) | Regular: 40-500HRC (337-509HV) Special: 52-56HRC (543-620HV) Special: 56-60HRC (620-713HV) | |

| Hardness Deviation | Maximum deviation range ±3.0HRC or ±40HV | |

| Microstructure | Homogeneous tempered martensite or tempered quartzite + diffusely distributed carbides | |

| Density | >7.20g/cm³ | |

| In acoordance with GB/T 18838.3-2008"High Carbon Cast Steel Shot, Cast Steel Grit", GB/T 18838.4-2008"Low Carbon Gast Steel Shot", SAEJ1993 High CarbonCast Steel Grit, IOS011124-3High Carbon Cast Steel Shot and Grit, JIS G5903 High Carbon Cast Steel Shot Cast Steel Grit ,JB/T 8354.4-2015 "Low Carbon Cast Steel Grit" , SFSA20-66 Cast Steel Abrasive,SAE J827 Cast Steel Shot. | ||

Application Scope

SS~2.5 SS~2.0 | They are useful for cleaning the surface rusting, oxide coating of large cast steel,cast steel workpiece. steel structure workpiece and large forgings. |

SS~1.7 SS~1.4 | They are suitable for the rust removal and strengthening,surface treatment before spraying, stone cutting of large and medium,castings, forgings, heat-treated workpieces,steel plate,steel tube,and structure steel. |

S~1.2 SS~1.0 | They are suitable for the rust removal and strengthening, surface treatment before spraying,stone cutting of medium and small castings, forgings, Heat-treated workpieces, steel plate, steel tube,and structure steel. |

SS~0.8 SS~0.6 | They are suitable for rust removal of small scale castings,forging, heat-treat pieces, Aluminum alloy steel castings,steel board,stee,plate,Steelpipe ,surface intensification of springs and chains, cuttincg of rocks,griding processing. |

SS~0.5 SS~0.3 | They are suitable for rust removal of alloy castings, thin plates, strinp steel, and small-sized stainless steel castings, spring strengthen surface treatment before plating, improving roughness, enhancincg adhesiveness. |

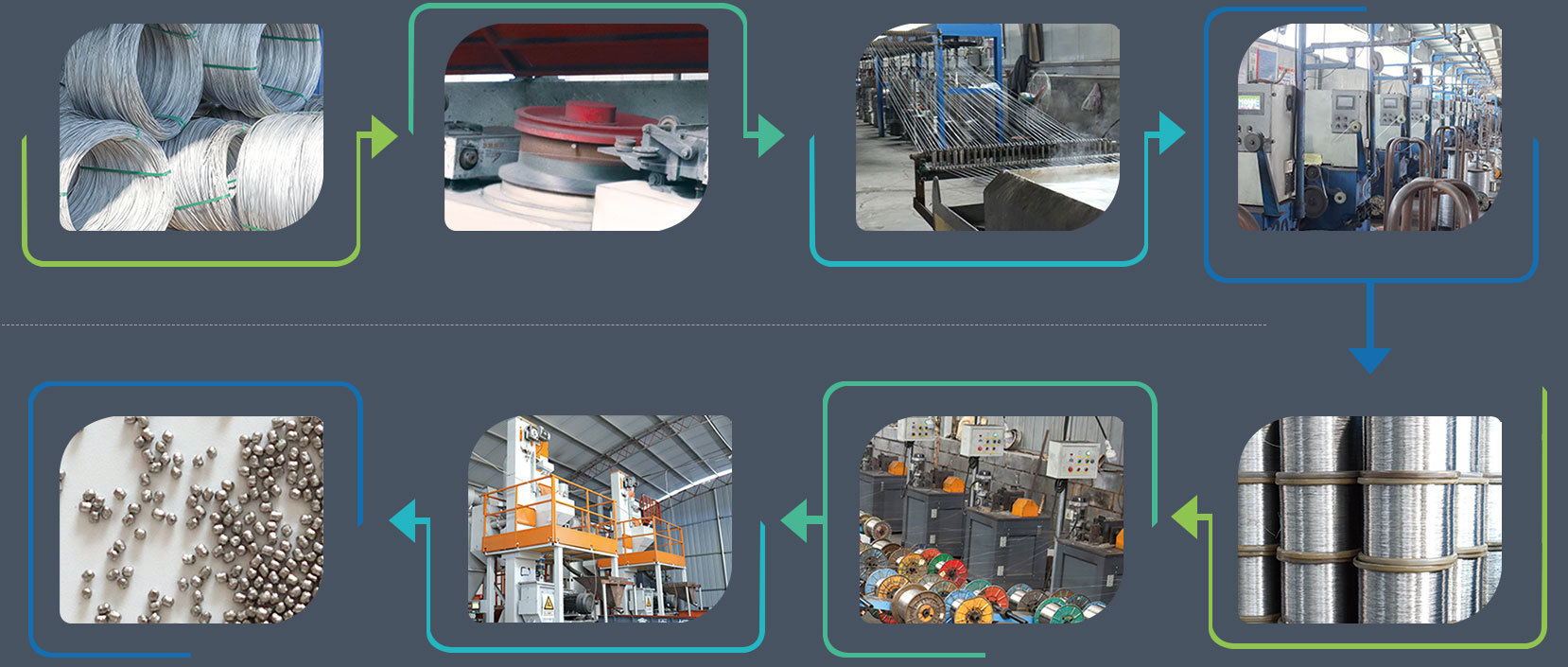

Production Processes

Our company has a professional full-process steel shot production process. All raw material suppliers are strictly controlled in accordance with the ISO quality system. The incoming metal coils are still inspected and analyzed according to standards. Before drawing, the surface is strictly cleaned (by using cleaning agents or mechanical methods). The drawing process is precisely controlled following the mechanical properties of the material. The Ra value of the wire surface is reduced from several microns of the coil to about 1.0 micron. The self developed silent automatic cutting machine cuts the wire into steel shot particles with consistent length and diameter. The proportion of shot particles with a length-to-diameter ratio greater than 2 is controlled below 5%. According to user requirements, through cyclic rounding, the G1. G2. and G3 standards are reached. Finally, the formed steel shots are screened and classified to ensure the consistency of shot particle sizes. The dimensional accuracy of steel shots is strictly controlled within a range of ±0.05mm, fully meeting users' precise requirements for the size of cut shots.

Production Strength

The company has an annual output of 8.000 tons of stainless steel and carbon steel wires and 6.000 tons of steel wires. Its products cover more than 120 specifications in 10 major categories. The products are widely used in industries such as shipbuilding, casting, machinery, locomotives, die-casting, and steel structures, and are highly recognized and praised by numerous customers, becoming the designated suppliers for many enterprises.

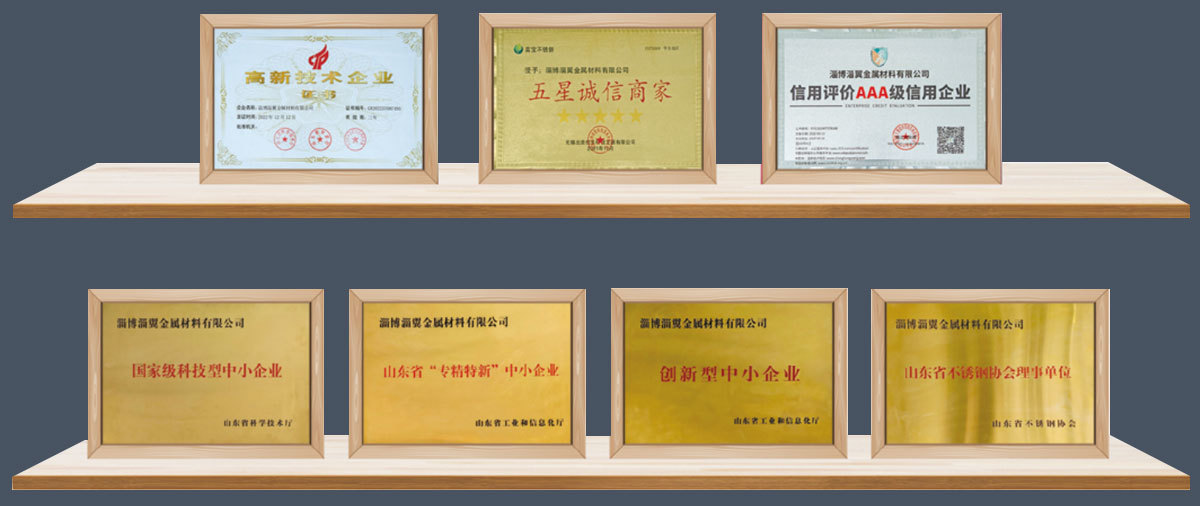

Certificates

The company attaches great importance to the control and management of product quality and always regards quality as the lifeline of the enterprise. Its products have fully passed the certifications of Quality Management System (ISO 9001:2015), Environmental Management System (ISO 14001:2015) and Occupational Health and Safety Management System (ISO 45001:2018), and have obtained the EU CE certification. This not only reflects the company's high-standard requirements for product quality but also demonstrates its responsibility for environmental protection and the health and safety of employees. Meanwhile, the company has been continuously committed to improving processes, optimizing products and upgrading equipment. With its powerful R & D strength and innovative spirit, it currently owns 3 invention patents for processes, products and equipment, and 4 software copyrights. It has also been successively recognized as a national high-tech enterprise, a small and medium-sized scientific and technological enterprise, an innovative small and medium-sized enterprise and a provincial specialized, refined, characteristic and innovative enterprise. In 2024, it was even approved for the Innovation Capacity Improvement Project for Small and Medium-sized Scientific and Technological Enterprises by the Science and Technology Department of Shandong Province. This series of achievements are undoubtedly a powerful affirmation of the company's technical strength and innovation ability, and also lay a solid foundation for us to provide customers with higher-quality and more efficient customized product services.

Honors

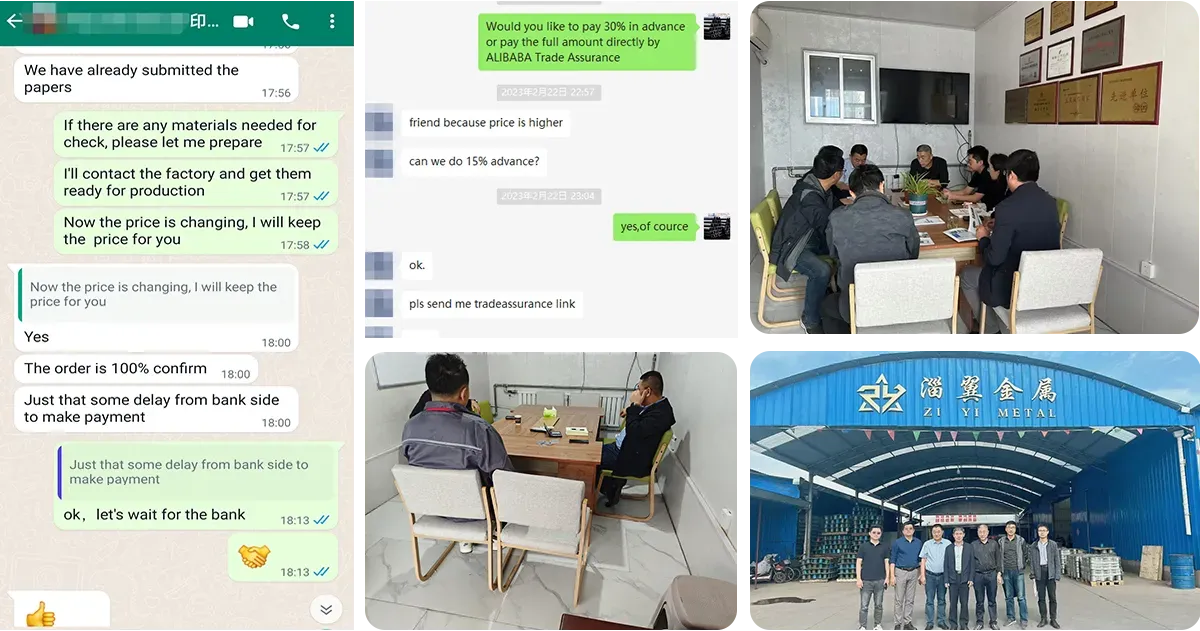

Customer Visits

The company adheres to the development concept of "people-oriented, strengthening enterprises with science and technology" and adheres to the values of "innovation, pragmatism, integrity, and win-win". With scientific management, advanced technology and excellent equipment, it wholeheartedly provides customers with high-quality products and services.

Packaging & Shipping

Zibo Ziyi Metal Materials Co., Ltd. is located in the Stainless Steel Industrial Park in Gaoqing County, Zibo City, Shandong Province. It covers an area of more than 20.000 square meters and is adjacent to National Highway 205. It enjoys a superior geographical location and convenient transportation. You are welcomed to visit our company for guidance or call us for inquiries!

We can pack according to customer's requirements, generally 25kg/bag or 1000kg/bag, can be tonnage plus pallet, can also be wooden crates plus bags.

Product Application

The company has an annual output of 8,000 tons of stainless steel and carbon steel wires and 6,000 tons of steel wires. Its products cover more than 120 specifcations in 10 major categories. The products are widely used in industries such as shipbuilding, casting, machinery, locomotives, die-casting, and steel structures, and are highly recognized and praised by numerous customers, becoming the designated suppliers for many enterprises.

FAQ

1)Q: Are you a factory or a trading company?

A:We are factory at Shandong,China.

2)Q: What is your MOQ?

A:Usually, it is 1 ton.

3) Q: What is your sample policy?

A:We can give you samples of less than 500 grams free of charge and ship them by courier.

4)Q: How about your delivery time?

A:The specific delivery time will depend on the items and quantity of your order.

5)Q: How to guarantee the quality of your products?

A: ① Strict detection during production. ②Strict sampling inspection on products before shipment and intact product packaging ensured.

6)Q: How do you control your product quality?

A:First, we are picking and testing samples from every step through the whole production lines, and there are several different inspectors to test the samples to guarantee the correct data. Second, we have our own Q&C center to pick up and keep the samples from every batch in order to trace the quality when our clients have questions.

7)Q: How do you ensure our long- term business relationship?

A:We are sincerely hoping to establish the good long-term business relationship with our esteemed clients, so we will do our best to guarantee our customers'beneft, stable quality and competitive prices are essential, and we are also provide our increasingly advanced technology for our clients' to meet the increasing needs in the current markets.

Other Products

Contact an expert now for a solution!

Please fill in the form below and we will contact you as soon as possible.

WORKING FOR OUR STAKEHOLDERS (CUSTOMERS)

Contact Information

No. 398 Gaozi Road, Gaoqing County, Zibo, Shandong, China.